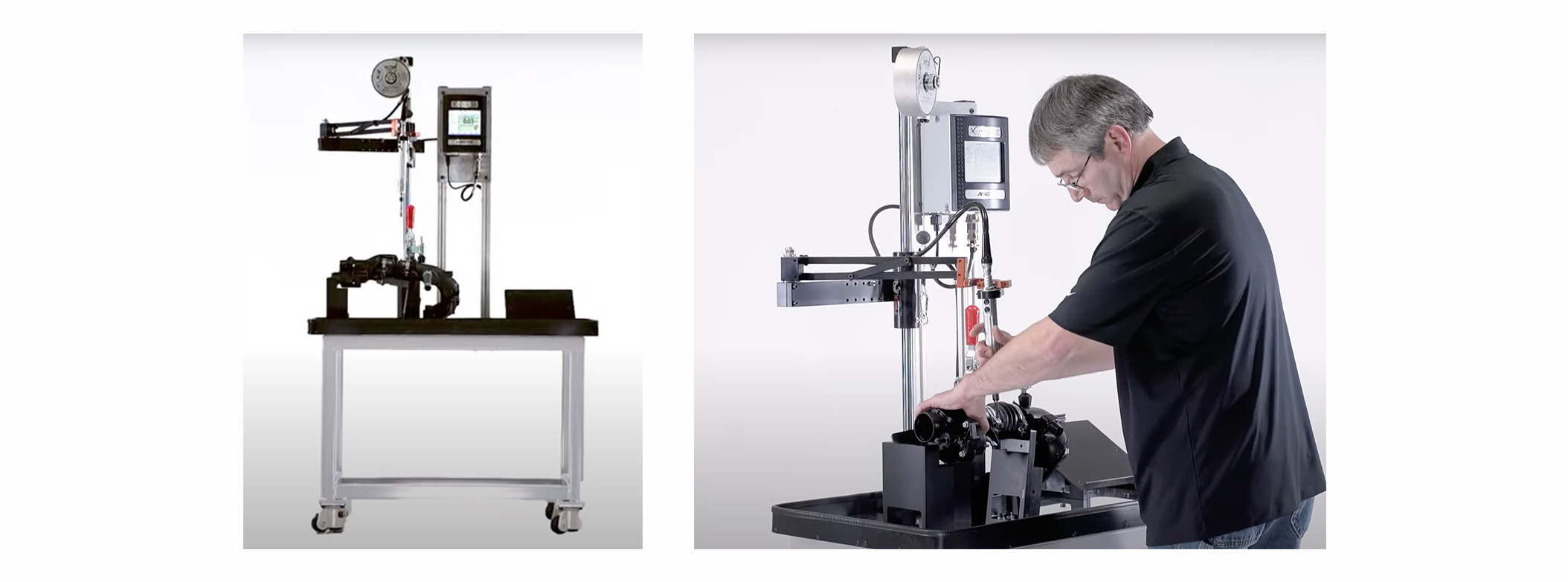

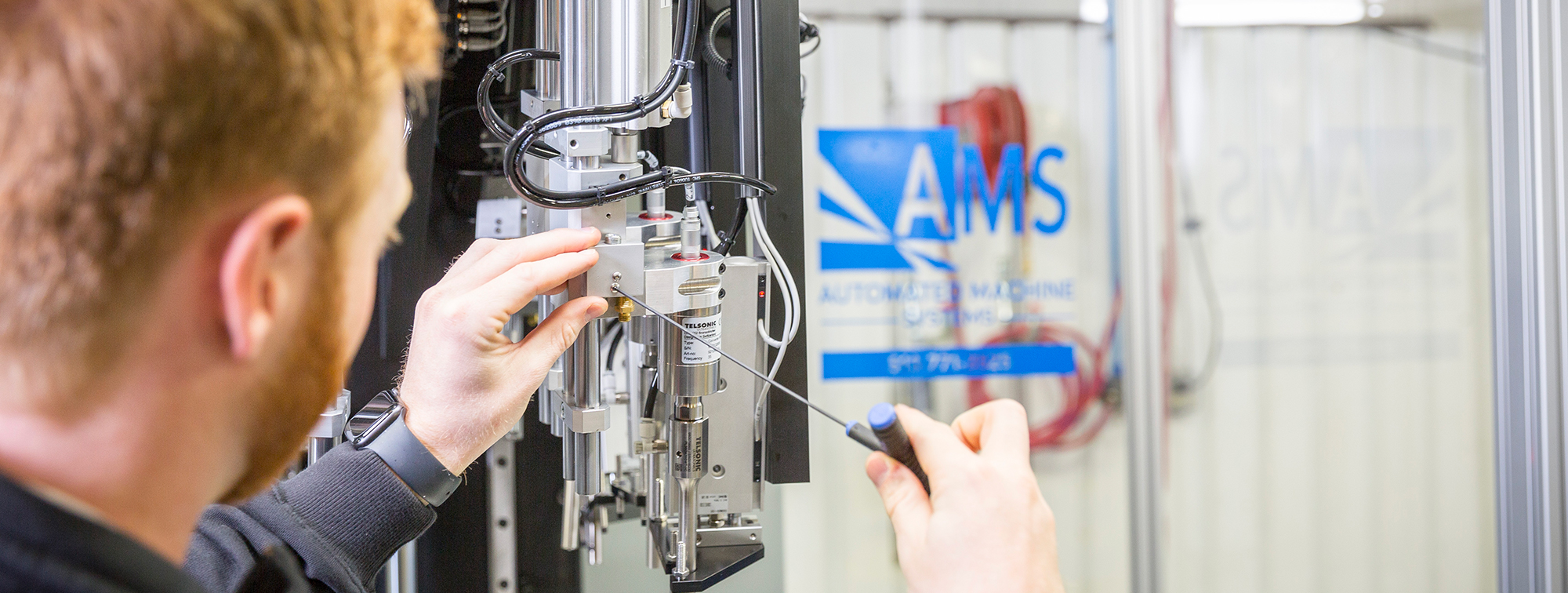

Cincinnati-based Automated Machine Systems uses a proven 17-step process to fully understand customer requirements, timeframe, and budget. Customers report a 97% satisfaction rating and 99.5% on-time delivery. Custom and engineered solutions include Leak Testing, Ultrasonic, Vibration, Seam, Textile, and Spot welding. Custom and engineered Robotic Assembly for inserts, clips, and nuts.

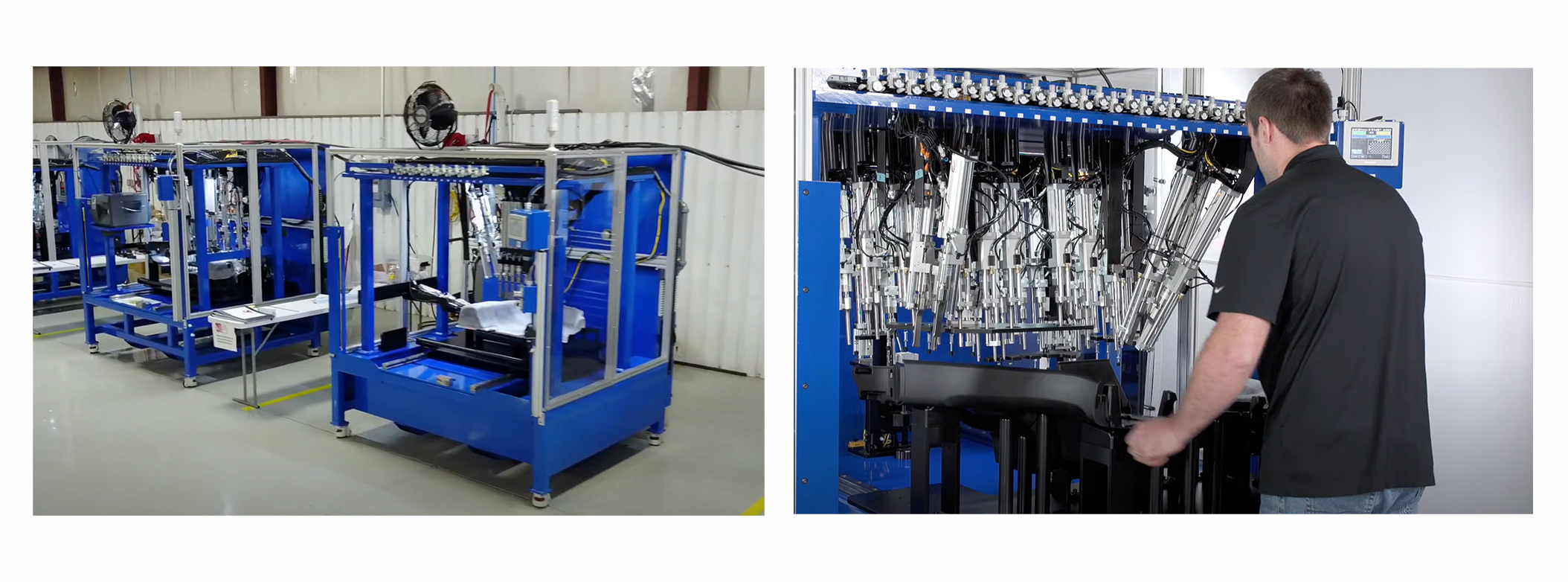

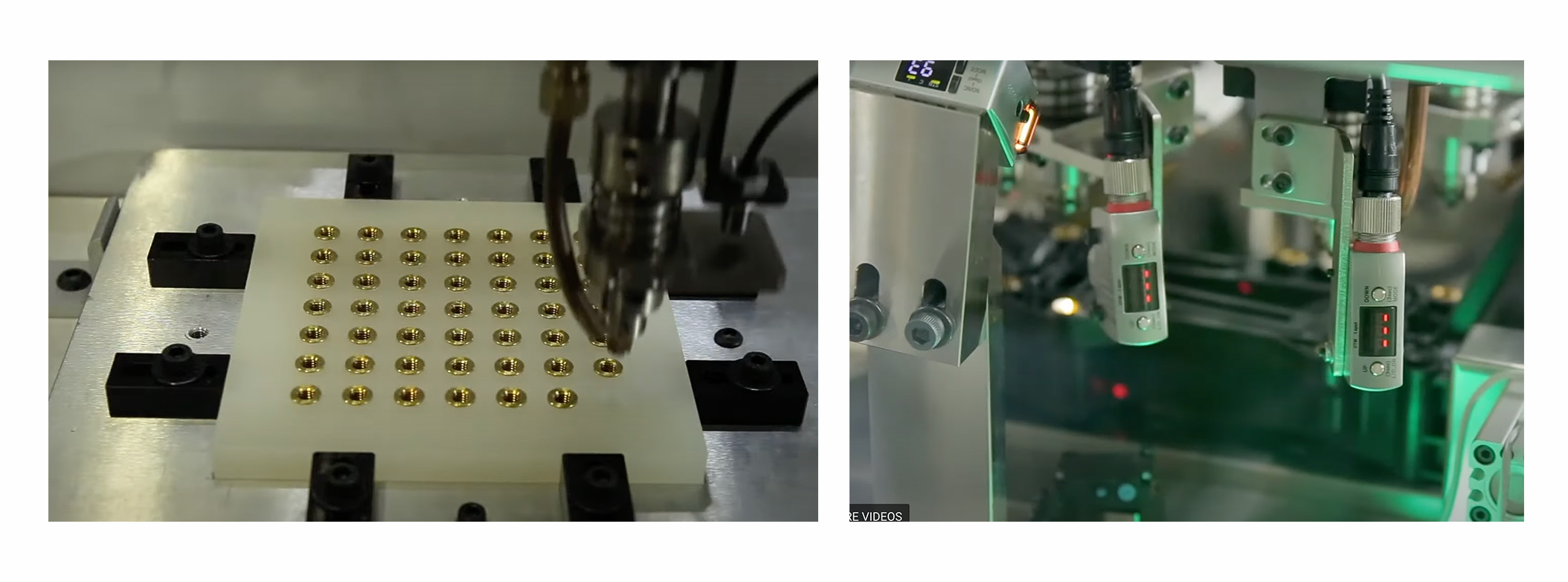

AMS collaborated with a large-format plastics injection molder in the Carolinas to automate a high-volume nut insertion operation for lawnmower assembly. Customer requirements called for six nuts to be inserted every 60 seconds within an automation cell managed by a single operator. AMS built two custom-configured Fanuc robots, doubling throughput, with minimal operating costs.

AMS collaborated with a large-format plastics injection molder in the Carolinas to automate a high-volume nut insertion operation for lawnmower assembly. Customer requirements called for six nuts to be inserted every 60 seconds within an automation cell managed by a single operator. AMS built two custom-configured Fanuc robots, doubling throughput, with minimal operating costs.